Understanding Horizontal Vessel Separator

Inside the Pressure Vessel

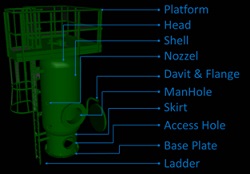

Therefore, let’s study the parts of the pressure vessel

1. Head

Head is the closing part of the vessel, as the name takes from English, it means head. The head itself is on the right and left for horizontal vessels, or for vertical vessels it is in the upper and lower parts. There are also various types of head itself, some are torisperical, shpere, ellipsnoidal, cone or even flange. All depends on the use and also from the pressure that works on the vessel itself. The type that we encounter most often is the ellipsnoidal type, in which there is a part called knucle.

2. Shell

A shell is a part of a cylindrical vessel, which surrounds the vessel itself. The shell is a sheet plate which is then formed (rolled) until eventually it becomes cylindrical. If the head is the head, the shell is the body or body. There is also a shell that does not go through roll process, usually it is forged.

A simple example like we saw in a fire hydrant, it has no weld weld in the middle part because it is directly formed from a plate.

3. Support

Support here is a buffer, where we know the vessel can not stand alone, he needs a buffer so he can stand. And that support is implanted support. As I explained in the previous article, the division of pressure vessels, where I once mentioned vertical and horizontal vessels. For vertical pressrue, we use skirts and leg supports, there are also some that use lug. As for horizontal vessels, we use the so-called sadle. The shape, like in the picture below.

4. Nozzle

Nozzel is a connection mechanism atanra vessel with piping. As we all know, a pressure vessel is a treatment unit, while piping is the path of the fluid to be treated. Now this fluid from piping will later be input into the pressure vessel, to combine the vessel and piping, that is the nozzle. The nozzel is basically a channel, where the channel uses a flange type connector. What is a flange? Flange is a mechanism for connecting one component to another. An example of a simple connection is the type of thread, for example we want to connect a balloon with a water tap, for example, between a water tap with a screw thread or a tread. The thread is the tightening media between the two components. Now if this uses the flange type,

5. Platform

The platform is actually not absolutely in a vessel, because there are certain vessels that do not need a platform. The platform itself is a place where people walk or place equipment in a ‘site’, more or less that’s the sense. The problem is it’s rather difficult to explain through words, but if you look at the picture above, hopefully you better understand the meaning.

The five most common parts above are the most common, other times maybe I will discuss the details of the pressure vessel

Separator vessel is a container that has the duty to separate fluid (from wells, wells) into several phases. Usually the phase that has been separated like the oil, does not necessarily be used as a result of production, but is still purified by the second to third separator, depending on its purification requirements. See the illustration below which divides the separator into 3 levels, High pressure, intermediate pressure and low pressure.

Separator is an important part in the processing industry (refinery), because in a chemical process we need tools that can separate and purify fluid, and this separator holds that role.

The function of the separator is to separate the resultant fluid from drilling into several phases by utilizing its specific mass. There is also a simple separation process, only using Baffles until there is also a complex. I once mentioned it in the article, the division of vessels based on the process

Separator vessels, can be distinguished based on geometrically into two parts, namely horizontal separator and vertical separator. Separator vessels can also be classified according to function, we get 3 types, namely two phases, vapor-liquid, and the last is 3 phases.

Horizontal Vessel Separator

Horizontal Separator has several advantages including that it can load more volume of gas or liquid, can separate into 3 phases, suitable for fluids that have medium to high GOR (gas oil ratio).

Because of its wide and long surface, this has both advantages and disadvantages for this horizontal separator vessel. The advantages, as mentioned earlier, have a large capacity as well as a relatively longer waiting time (residence time, for fluid). Besides that, his weakness is that he actually eats places.

The question is, why does it take time to wait (residence time or retention time)? Basically, all the fluids if left unchecked will separate themselves through its density, the heaviest density is below while the lightest will be above. Take a look at oil and water, the oil will separate above.

But when the fluid flows from a well or well, the fluid is in the form of a mixture and we cannot immediately separate it, it can be poured and then awaited, but the process is interrupted. In order to keep it separate and keep flowing, a separator is used, which of course also requires residence time.

Another advantage is that this horizontal type separator is cheaper than vertical, requires a smaller diameter with the same gas capacity, easier when transported because of its shape that is already sleeping.

Horizontal separator vessels are divided into two parts, one type is the conventional horizontal separator as we discussed above. Another type, is a horizontal double-barrel separator. The horizontal separator double-barrel shape is as shown next.

The difference between the two phases and the three phases of the separator lies in the phase which they form as output. Two phases usually only separate liquid (liquid) with gas only. Whereas for the three phase separator vessels, the liquid is separated again into oil and water, so the phase which is separated entirely is liquid (search) oil, liquid water, and gas.

Working Principle of Horizontal Vessel Separator

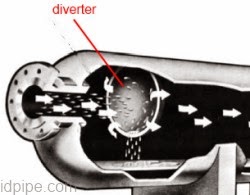

The working principle of a horizontal separator is that when a flow occurs, the flow from the inlet will hit the diverter which separates most of the gas from the fluid. The fluid will then trickle down, while gases that are filled in space tend to be continued. Because the gas still contains a little of water vapor, or the term droplet, the function of the mist eliminator will take the role of purifying the gas and separating the liquid which is still contained in the gas.

Vertical separator vessel

Then what to do with the vertical separator vessel? what are the weaknesses and disadvantages compared to vertical separators? What is the difference between a separator vessel and a knock-drum?

To discuss all that, I will separate the material from the vertical separator vessel horizontal separator. Besides that, I will write some comparisons as well as parts of the separator, so please read the article on the continuation of this material in understanding vertical type vessel separator