Winsketel Thermal Design

Winsketel Thermal Oil Heaters

Thermal Oil Guide Winsketel Thermal Desingn

- Thermal oil system features

1.1. Introduction

Thermal oil or thermal fluid is used to carry energy in heating applications, industrial processing and also industrial refrigeration. Thermal oil is most suitable for use in high temperature applications where the most optimal operating conditions are between 150ºC to 350ºC. At this temperature, heating using Thermal oil / thermal fluid will have the highest efficiency compared to other heating methods such as using steam, electric or direct fired.

The use of thermal oil systems has begun since the late 1930s. Thermal oil is widely used because of its energy efficiency and high heat transfer rate. However, at that time, the thermal oil used was not stable so that if the operating conditions temperature slightly exceeded the reference temperature, it could cause thermal oil to be damaged or partially oxidized. As a result, several decades later many companies returned to using the option that was felt to be safer, namely the use of steam, although this system was more complicated than thermal oil.

At present, as long as the thermal oil heater is properly designed by experienced producers and followed by the selection of the right thermal oil and well maintained, the thermal oil system will be safer to use than the steam system.

At present, there have been many significant advances in thermal oil technology. Thermal oil is now much more stable at high temperatures, non-toxic and can reach higher temperatures than before. This is because many thermal oil manufacturing companies are researching and developing this thermal oil technology as one of their business fields.

There are many reasons why users return to thermal oil. One of the main reasons is: thermal oil systems are non-pressurized systems. Instead the steam system / steam operates at high pressure in accordance with the desired temperature. In accordance with the curve, the saturated steam pressure will increase with the desired temperature. The use of the steam system must also follow the work safety regulations in force in the country. This results in the installation of a steam system being more expensive and also requiring routine insurance inspection requirements.

1.2. Application of Thermal oil The

liquid used for heat transfer media is generally referred to as Thermal fluid. Water is the easiest thermal fluid to obtain with a high enough heat transfer efficiency and easy to control, but the disadvantage is its limitations on its physical properties which will boil and turn into steam at temperatures above 100 ºC. This results in the operation of water at temperatures above 100ºC requiring pressurized systems.

The advantage of thermal oil is that it has a higher vapor / boiling point which is in the range of 300 – 400 ºC depending on the type of thermal oil. As long as the operational conditions are below the vapor point, there will be no phase change in the thermal oil. Therefore the thermal oil system can work at low pressure to produce the desired high temperature.

1.3. Overview

Thermal oil is one of the most widely used thermal fluids in various applications and industries where high temperatures are required. Some products are used in space, automotive, shipping or military applications. Other applications in process equipment, engines, compressors, piston pumps, gears and so on. Thermal oil is also widely used in food, beverage and pharmaceutical applications.

The following are some examples of the use of thermal oil in various industries:

• Chemical Industry

• Plastic & rubber processing

• Textiles and Laundry

• Food processing

• Oil and Gas Production

• Wood

processing • Plastic & rubber

processing • Paper, cardboard and derivative processing

• Industry Shipping

• Building Materials

• Metal processing

Thermal oil also has advantages to be used at several temperature levels at once. One unit of thermal oil heater can provide heat requirements on several circuits / temperature loops at once. For example a Thermal oil heater with an operating temperature of 300 0C, can be used for other thermal oil circuits with 3 operating temperatures: 300 0C 240 0C, 150 0C with each temperature having its own circuit.

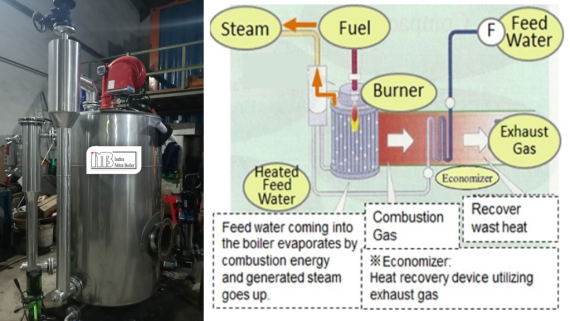

In some processes, sometimes factories still need steam in addition to the heating process, for example for sterilization with Autoclave or boiling with steam or drying using Rotary Drum By using Thermal Oil, the factory can still avoid using boilers by utilizing Thermal oil to produce steam uncontrollably. directly by using OSG (Organic Steam Generator). A combination of Thermal and Organic oil Heater

This Steam Generator can produce steam with a variety of pressures, both low, medium and high pressure. OSG is a Steam Generator to produce steam. The working principle is different from a boiler that uses fire directly to heat water in a boiler pipe. OSG is an indirect steam generator where thermal fluid at high temperatures will be used as a heat source to convert water into water vapor (steam) so it is safe to be placed in a closed room.

Because of the above features, high flexibility and easy maintenance, the thermal oil heater is quickly re-used by various industries as a heating process.

2. Thermal fluid vs. Steam

Comparison of thermal fluid with the Steam System Even though the thermal oil system has been used since the 1930s, its use was once avoided by the industrial world. The reason is the lack of information and limited knowledge on how to design, operate and maintain

a good and correct thermal oil system . As a result of this ignorance, many thermal oil users have switched to using a steam system for heating purposes. Based on available information and facts, the thermal oil system will actually be superior to the steam system if it is properly designed, operated and maintained according to manufacturing recommendations.

2.1. Safety, Environmental and Legal Requirements

To transfer heat to most processes, the steam system must operate at high pressure in accordance with the steam table. For example, at 200ºC, saturated steam will have a pressure of 16 bar, while at a temperature of 300ºC, saturated steam must be at a pressure of about 110 bar. Conversely, at this temperature, the thermal fluid system operates at atmospheric pressure. Pressure on thermal oil is only obtained from pumps that are designed to be sufficient to overcome the pressure drop from pipes and other components while maintaining turbulence.

Operating the system at atmospheric pressure has more advantages than high pressure. Systems that operate at high pressure must meet legal standards and applicable regulations. As a result, higher installation costs are required and specialist engineers are needed to operate them. In contrast, the thermal oil system has operational conditions at atmospheric pressure so that it can be handled by operators in general. Therefore, if the thermal fluid system is designed by an experienced company and operated according to instructions, there will be no problems.

2.2. Efficiency

The steam system experiences a lot of heat loss due to condensation especially at high temperatures above 200ºC. It is estimated that the energy loss due to flash (including steam traps etc.) is generally around 6% – 14% of the total energy. 2% loss is caused by blowdown and 2% by deaerator. Conversely, the thermal fluid system does not experience the flash loss. Thermal fluid also does not require water treatment at all. The potential for fouling due to heat flux in the thermal oil system is lower than the steam system.

As a result of all the factors above, the thermal oil system at operating conditions above 200 ºC can be 15-30% more efficient than using a steam system.

2.3. Corrosion

Steam systems are also known to have corrosion problems. Air combined with hot water, and other contaminants in the iron pipe will cause metal corrosion. In environments that have high levels of lime and mineral water, the system must be equipped with appropriate water treatment to prevent the formation of scale in the pipes. This scale will inhibit the heat transfer between the hot gas produced by the burner and water in the boiler. Because a lot of heat is not absorbed by the boiler, the boiler capacity will decrease and fuel consumption will increase. If this continues for a long time, the boiler pipes will overheat and potentially damage. In the thermal oil system,

2.4. Temperature Control The

steam system uses pressure control to control temperature. With dependence on complex pressure equilibrium, accuracy is generally limited to a range of around ± 6ºC. The range of values will be even greater if the system is getting old and corrosion begins to emerge. In comparison, the thermal fluid system can have an average temperature control of ± 0.8ºC. This precision is achieved by efficient measurement and mixing with a cooler return fluid with thermal fluid from the supply line with a 3-Way valve.

2.5. Environmental Safety

Water in the steam system must be treated chemically in advance to reduce corrosion. The results of steam and condensate blowdown cannot be directly discharged into the gutter because it will cause danger to the environment. Conversely, the thermal fluid system does not occur at all blowdown because the thermal fluid system is a closed system without the need for liquid disposal. Disposal is only done after the thermal fluid is degraded, which is around 8-10 years.

2.6. Safety / Safety

To conduct heat, usually a steam system must operate at high pressure. According to the steam table, at 300ºC for example, saturated steam is at a pressure of 110 bar. Or at 200ºC the saturated steam pressure is at 16 bar. This is different from thermal fluid systems, most thermal fluid systems are ventilated into the atmosphere. The pressure is only 10 at the pump pressure which is able to overcome the friction loss of pipes and other components while maintaining turbulent flow conditions.

Therefore, a properly designed thermal fluid system will be safer and easier to operate than a steam system and will usually have less problems.

2.7. Maintenance of the system / Maintenance

Steam system requires constant and continuous maintenance, especially on supporting equipment such as steam traps, valves, condensate return pumps, welding joints, expansion joints as well as water analysis and water treatment systems. In a 4-season country, if there is a power failure in cold weather, the steam system can freeze which can cause the pipe to burst and damage to supporting components.

Conversely the thermal oil system does not require traps, condensate returns, blowdowns and also chemicals for water treatment purposes. In the 4-season state, the selection of the right fluid will not freeze below zero degrees. The thermal oil system has been proven to operate safely and efficiently for decades with minimal maintenance costs.

2.8. Investment and operational

costs The initial purchase cost of a steam / steam system may be cheaper than a thermal oil system. However, the payback period for replacing the steam system with a thermal fluid system will be rapid due to reduced operational costs, maintenance costs and environmental problems. Increased production and product quality can occur due to better temperature control. The use of thermal oil can also increase safety factors and reduce labor costs

3. Thermal fluid system design

In recent decades there have been many advances in research and development of thermal oil systems both in terms of fluids, tools and systems. This increased understanding results in a decrease in the risk of incidents such as fire, leakage, etc. thereby restoring user interest in thermal oil. Even though the system is simple, the Thermal oil system must be perfectly designed. Thermal oil is a closed loop system where the designer must also take into account the flow rate, pressure drop, volume change and thickness etc.

3.1 Design

Figure 3.1: Piping in a Thermal Oil System

Information on Figure 3.1

(1) Thermal fluid Heater,

(2) Thermal fluid Circulating Pump,

(3) Safety Relief Valve,

(4) Thermometer,

(5) Pressure Gauge,

(6) Thermal fluid Heated Equipment,

(7) Bypass Valves to maintain full flow to

heaters,

(8) Expansion Joints

(9) Anchor and Pipe Guides,

(10) Expansion tanks,

(11) Vent Piping,

(12) De-aerator Tanks,

(13) ) De-aerator Tank inlet,

(14) Thermal Buffer Tank,

(15) Catch Tank for drain pressure relief

valves, cold seals, expansion tanks & vent,

(16) Gate Valve,

(17) Strainer,

(18) System Fill Connection,

(19) Flexible Connection,

(20) Isolating Valve,

(21) Manual Low Level Test Line,

(22) Manual High Level Test Line.

The thermal oil system provides an efficient heat source for processes that require high temperatures, even up to 400ºC. Operationally the use of thermal systems. oil will be cheaper and will usually require less maintenance than a steam system. In addition, thermal oil will be more thermally efficient and not release heat into the atmosphere through traps and leaks such as steam systems. However, although thermal oil systems are a better choice overall than steam systems for high temperature applications, users of thermal systems oil is still not as much as a steam system. Past events due to imperfect thermal oil design and improper liquid selection have led to a number of incidents that left a negative view on the use of thermal fluid.

In fact, the thermal fluid system is safer than the steam system as long as it is designed, used and maintained properly. The main advantages lie in the low operating costs, simplicity of design and system security due to low operational pressure. In general, thermal oil systems consist of heating coils, burners, circulation pumps and ventilated expansion tanks. Expansion tanks can be emptied by filling inert gases such as nitrogen to prevent liquid oxidation but are usually discharged more frequently into the atmosphere.

3.2 Factors influencing the design of a thermal oil system

A thermal oil heater must be designed based on thermal load requirements including process, operating temperature and flow conditions requirements. When calculating thermal loads, heat loss must also be taken into account, which usually ranges from 10% to 20% of the total load. In addition, the designer also needs to choose fuel (gas, diesel, coal, electricity or biomass), vertical or horizontal position, the amount of flow (indicating how many times the combustion gas will pass through the coil to heat the thermal fluid can be two, three or four).

All of these things are considered based on operating parameters, fuel, available area

and efficiency.

3.2.1 Selection of Heating Coil

heating coil instructions generally consist of 2 parts, namely the inner coil (inner coil) and the outer coil (outer coil). Thermal oil is pumped into the outer coil by a circulating pump from the top then flows inside the coil at a certain speed and finally the coil exits and is re-distributed to the media to be heated. While the flames from the burner will enter the combustion chamber which is part of the receiver of

radiant heat from the inner and outer coil to the space between and then to the outside of the outer coil to the exhaust in the chimney / chimney. The heat resistance between thermal oil and hot gas occurs counter current to get the highest efficiency.

Because thermal oil works at high temperatures, the temperature of the flue gas will be slightly higher than the temperature of the thermal oil coming out of the heater. The heat contained in this Flue gas can still be used to save fuel usage by using it as an air heater before entering the combustion chamber. Each increase in the intake air temperature of 10 0C, fuel savings will be around 0.4 – 0.5%. So if the combustion air can be raised to 130 0C, there will be an increase in temperature of 100 0C and fuel savings around 4-5%. This utilization feature can only be used on a burner that is united with thermal oil and is often called an air jacket.

A more complete explanation of the heating coil will be discussed in chapter 4

3.2.2 Selection of Burner

Burner is one of the main components of the thermal oil boiler because the burner is: the place of combustion. The choice of burner is crucial in Thermal oil operations which usually work non-stop. The burner must be placed in a position that is easy to do service. In thermal oil with a small capacity, usually the manufacturer will provide a package burner that is a burner purchased from a burner supplier. As for the larger capacity, the burner will become one with thermal oil. A more complete explanation of the burner will be discussed in chapter 5

3.2.3 Determination of Pumps.

The pump functions to distribute the oil heated by the heater to all heat users. Important factors in pump sizing are pressure, flow rate and temperature. Pump pressure must be able to overcome the pressure drop caused by friction in the vertical head, friction in the pipe, and other pressure losses due to fittings, valves and so on. The pump must also be designed so that the flow rate is sufficient to supply to all systems that require thermal oil heating. The pump must be able to operate at a minimum of 350oC and use mechanical seals with air cooling. A more complete description of the pump will be discussed in chapter 6

3.2.4 Selection of Expansion tank

Physical properties of Thermal oil is that its volume will increase when heated. Therefore a thermal oil system must have an expansion tank of sufficient size to anticipate the addition of volume of thermal oil in the system. Another thing that must be considered is the total volume of the system (including pre-filling the expansion tank), operating temperature and the coefficient of fluid expansion. After the piping system design is complete, the amount of thermal oil needed for the entire system is calculated, namely the volume of the entire pipe plus volume of thermal oil in the heating coil.

The average volume of thermal oil will expand about 10% for every 100 degree increase. For example, if the volume of thermal oil in the system is 2000 liters and operates at 250 oC, then an ambient temperature of 30 oC will increase 220 oC or 22% expansion . The expansion volume of 440 liters is what the expansion tank must accommodate.

The level in the expansion tank should always be maintained in the middle – that is, not less than the 25% level and not more than the 75% level. The rule of thumb sizing expansion tank is twice the volume of expansion. So in the example above, the expansion tank volume is 880 liters. A more complete explanation of expansion tanks will be discussed in chapter 6

3.2.5 Selection of thermal fluid

The selection of the correct thermal fluid must be adapted to the application because it can affect system security, heat transfer, operating temperatures and so on. Therefore users must provide precise and accurate information and operating conditions to thermal oil producers before they can provide appropriate fluid recommendations.

There are many manufacturers of Thermal fluid. In general they sell Thermal fluid in

three categories, namely:

• Hot / mineral oil

• Synthethic

• Others including silicon

A more complete description of thermal fluid will be discussed in chapter 7

4. Heating

Coil Thermal oil heater capacity is determined by the amount of heat duty / thermal load requirements of a process, operating temperature and thermal oil flow rate. When calculating this thermal load, heat loss must also be calculated in the range of 10% to 15% of the heat duty. Heating coil capacity can be calculated after the thermal load is known. Usually Heater will work at 70 – 80% below the maximum capacity.

The thermal oil heater construction can be vertical or horizontal and consists of 2 passes, 3 passes or 4 passes. The number of passes indicates how many times the combustion gas will pass through the coil. Fuels that can be used are gas, diesel, coal or biomass. The code for making coil usually follows the code regarding the construction of the Boiler and Pressure Vessel.

Figure 4.1 Heating coil after rolling without cover.

Tube used for making coil is boiler tube with high grade. Each coil consists of several tubes which are rolled up simultaneously. The diameter of the tube is adjusted according to the flow rate in the tube and the desired pressure drop. In small and medium capacity thermal oil (below 3,000,000 kcal / hour) the inner coil and outer coil will be connected in series and the hot gas from the burner combustion will flow there is an outside in the opposite flow (counterflow). Whereas at a greater capacity, the inner coil and outer coil will be connected in parallel. The connection between the tube and the tube is welded with argon welding and X-ray testing is performed on each connection and pressure tests up to 30 bar.

Figure 4.2 Photo of Winsketel Thermo Oil Heater with various sizes

Thermal oil in the heating coil will receive heat from the hot gas combustion results in the burner then this thermal oil will provide heat to the media to be heated. Thermal oil that has been taken by the heat media will be colder and return to the thermal oil heater to be reheated. Heating coil generally consists of 2 parts, namely the inner coil (inner coil) and the outer coil (outer coil). Thermal oil will first be pumped into the outer coil from the top then flow in the inner coil with a certain speed and time then finally come out of the coil to be distributed to the media to be heated. Meanwhile,

Thermal oil and hot gas flow is counter current flow to get the highest efficiency. Vertical construction is recommended to avoid trapping air inside the coil. Another advantage of vertical construction is that the heat distribution by the burner will be evenly distributed on all sides of the coil. Meanwhile, if thermal oil is installed horizontally, heat will tend to be higher at the top of the coil. Because thermal oil works at high temperatures, the temperature of the flue gas will be slightly higher than the temperature of the thermal oil coming out of the heater, so the flue gas heat should be used to save fuel. The most appropriate way to utilize the high temperature flue gas is to warm the air before it is used in the combustion burner.

5. Burners

The selection of a Burner

Burner is an important component of a thermal oil heater because the burner is the place of combustion. The principle of combustion is a mixture of fuel (hydrocarbons), oxygen and also the lighter. generally the fuel used is liquid fuel (diesel oil and fuel oil) or gas. Sometimes there are also those who use solid fuels such as biomass or coal. In this chapter the discussion is limited to liquid and gas fuels.

In general there are 2 types of burners. First is the burner that is purchased separately from the thermal oil heater is often called a Packaged Burner. The second is a burner integrated with a thermal oil heater, often called an Integrated Burner. In thermal oil with a small capacity, it is recommended to use a package burner because the initial investment is lower. As for medium and large capacity, it is recommended to use an integrated burner. Another advantage of using the integrated burner is that it is possible for thermal oil heater manufacturers to use the air jacket feature on the flue gas which can be used to preheat combustion air.

Because the temperature of the flue gas is still quite high, ie above 200 oC, the flue gas can be used as air heater before entering the integrated burner. Every 10 oC increase in combustion air temperature will get fuel savings of 0.4 – 0.5%. If there is an increase in combustion air temperature from 30 oC to 130 oC, there will be savings of 4-5%. If thermal oil users want to obtain higher efficiency, then a heat recovery system can be added which uses hot water or steam media where the combustion air / flue gas can be cooled to 125 – 150 oC.

6. Accessories

6.1 Pump

The thermal oil pump is an important part of the thermal oil system because it will determine the smooth operation of the thermal oil system. In the standard thermal oil which is where the distance of the heat user is close to the thermal oil (without special installation), the manufacturer of the Thermal oil heater is usually already equipped with a pump according to the optimal flow rate and pressure taking into account the appropriate motor. oil still in cold conditions The viscosity is higher so it requires a motor with more power than in hot conditions. But in special installations, where the distance between the heat user and the thermal oil heater is far enough it is necessary to redesign the pump from the manufacturer. The pump must be carefully designed, especially taking into account the flow rate and pressure. Thermal oil pumps should be chosen which use water coolers. However, because this type of pump is less popular and is considered quite troublesome, in Indonesia more air-cooled pumps are used rather than water-cooled. Picture

6.1 Circulating centrifugal pumps The suction and discharge pumps must be equipped with a pressure gauge to determine the performance of the pump and to find out the pressure drop in the system. From the pressure gauge will be known if there is a decrease in pressure compared to normal conditions which is usually caused by a clogged filter / filter. If the pressure gauge moves up and down quickly it can indicate the presence of air or water in the system. Problems such as these must be addressed immediately to prevent damage to the mechanical seal.

Another thing that must be considered is the alignment factor. The coupling connecting the pump to the motor must be checked for its alignment level periodically. 19 alignment coupling checks are performed when the thermal oil conditions are cold. This alignment problem in the long run will be able to damage the mechanical seal due to high rotation. Mechanical Seal pumps that often suffer damage other than indicating the existence of misalignment can also be an indication that the formation of particles has occurred in the thermal oil.

In more complex Thermal oil systems, for example, it requires 2 or more temperatures and / or is used to produce Steam through OSG (Organic Steam generator) requires several pumps whose flow rate capacity is adjusted to each circuit.

6.2 Expansion Tank

Physical nature of thermal oil is that its volume will increase when heated. This phenomenon must be considered when designing a thermal oil system. A well designed thermal oil system must have an expansion tank that is sufficient in size to accommodate the additional volume of the system. Other things to consider are the system volume (including pre-filling the expansion tank), operating temperature and the coefficient of fluid expansion. Because the volume of thermal oil will expand at different rates, the capacity of the expansion tank must always be ensured of the type of thermal oil before filling the system.

The average volume of thermal oil will expand around 10% for every 100 ° C increase. For example if the volume of thermal oil in the system is 2000 liters and works at a temperature of 250 oC, then an ambient temperature of 30 oC will increase 220 oC or 22% expansion. The expansion volume of 440 liters is what the expansion tank must accommodate. 20 We recommend that the Level in the expansion tank be maintained between the lowest level of 25% to the highest level of 75%. The rule of thumb sizing expansion tank is twice the volume of expansion. So in the example above, the expansion tank volume is 880 liters. If an additional circuit occurs and the installed expansion tank capacity is insufficient, an overflow tank must be provided under the expansion tank.

At the lowest level of the expansion tank must also be equipped with a level switch that is connected to the alarm to give a warning that there has been a leak in a closed circuit of thermal oil. A decrease in the oil level in the expansion tank will be clear evidence that the volume of thermal oil in the system has decreased and a leak must be sought immediately.

6.3 Drain tanks / Overflow tanks

Drain tank is useful as a final reception to accommodate all the volume of oil that is in the Overflow tank circuit is used to accommodate thermal oil that spills / overflow from piping installations. In systems with very long pipe installations, the volume of oil that is expanded during the process can exceed the volume of the expansion tank, so that sometimes thermal oil will run out of the expansion tank and be accommodated by Overflow tanks. Drain tanks can also function as overflow tanks. Drain tank / Overflow tank is equipped with low level control and a small pump to pump thermal oil back to the expansion tank when the thermal oil level in the tank touches the low level control. This situation is caused by the system being stopped so that the volume of thermal oil will shrink again.

6.4 Flow control

In the piping system which is the artery of the distribution of thermal oil, it must be equipped with flow control in order to guarantee a smooth and continuous flow of fluid in the heating pipe and coil. This flow control will be connected directly to the burner and equipped with an alarm. If there is damage to the pump, filter clogging or other problems that cause the condition there is no flow in the pipe, this problem will be immediately detected by the flow control and will instruct the burner to stop so that no more heat is given to the heating coil.

This emergency stop is used to protect thermal oil, because if the burner continues to work when the flow decreases / there is no flow, then the thermal oil in the pipe will overheate which will cause oil coking or capping. This coking event will reduce the ability of thermal oil as a medium for conducting heat. Thermal oil will clot and stick inside the pipe so that it prevents heat transfer from the hot gas produced by the burner to the thermal oil

If the coking process is continuous for a long time, the charcoal layer will thicken and further disrupt heat transfer. Because of overheating, coking can cause cracks in the pipe and continue to leak thermal oil. This condition must be avoided and anticipated from the start. In extreme conditions when the burner continues to provide energy to the immovable thermal oil, the temperature will rise rapidly even beyond its auto ignition temperature. In the event of a crack in the heating coil or pipe, the thermal oil that leaks into the environment can spontaneously combust. While if the pipe is in good condition, Evaporated thermal oil may be wasted through a relief valve and into the drain tank or another possibility is to push thermal oil into the expansion tank and into the catch tank. Discharges that can suddenly cause a fire because the steam from hot thermal oil is flammable when exposed to ignition.

There are several ways to install flow control:

1. Mechanical flow switch on the main oil flow

2. Differential Pressure Flow Switch

3. High Pressure Regulating Valve between line suction and pump discharge

To avoid all of the above incidents, which might occur because the poblem has no flow, a low flow shutdown interlock on the burner safety must be made. The most effective system is a pressure sensor because it has proven to be a reliable system for the long term. To give an indication of the state of no flow, the factory can install a pressure sensor

6.5 Temperature Control Temperature control

requirements also determine the system design. Within the modulation range of the burner, most heaters can control temperatures up to ± 3ºC. If the user requires very precise temperature control, a dual circuit system can be used. With a dual circuit, the primary circuit will operate with a higher temperature of 10ºC to 30ºC above the temperature of the secondary circuit. This dual circuit can also be used on systems that require two different thermal oil temperatures. If heating of three different temperatures is needed then a triple circuit can also be used.

6.6 Electric Control Panel

The process control system chosen for the thermal oil system must comply with the HSE standard. This depends on where the laying of controls and thermal oil used must be appropriate. If the location is a hazardous area, all possible explosions must be considered. All electrical equipment in the system must be designed according to its safety classification. In addition to ensuring that all electrical equipment complies with HSE standards, the thermal oil control system must also be properly designed to include all safety interlocks, such as temperature and interlock flow interlock which will automatically turn off the heater connected to the hardwire as an emergency stop.

Modern thermal oil system designs usually use PLCs to transfer data and information. The use of PLC allows users to control processes sequentially, view feedback information from the system and to interact with the process system. The use of PLCs for thermal oil systems allows for more precise control and information about the operating conditions of the process is better available. Electric control for Thermal oil consisting of temperature control, flow control and also control electric current. For temperature control, the temperature sensor is placed on the thermal oil and in the exhaust chimney. The sensor on the thermal oil will regulate the modulating burner while the temperature sensor on the exhaust gas will be used as safety on the system. Under normal conditions, the temperature of the exhaust gas is 20 – 50 oC above the temperature of thermal oil. If the temperature exceeds this range, it can be concluded that there has been an overload on the system because the heat transfer from the burner is less absorbed by thermal oil so a thorough check on the system must be carried out. The reason could be due to a leak in the pipe, or a leak in the combustion chamber. Burning thermal oil with the fuel in the burner will cause the exhaust gas temperature in the chimney to rise. The symptoms

Another indication of leakage is the appearance of black smoke in the chimney because the leaked thermal oil does not burn completely by the burner.

7. Thermal Oil Liquid

7.1. Types of Thermal Oil

The selection of thermal oil must be adapted to the application because the type of thermal oil used can affect system security, heat transfer, operating temperature and so on. Therefore users must provide precise and accurate information about operating conditions to thermal oil producers before they can provide appropriate fluid recommendations.

There are several types of heat transfer fluid available on the market. Thermal fluids for heating purposes can be categorized by their chemical structure into three main groups:

• Hot / mineral oil

• Synthethic

• Others including silicon

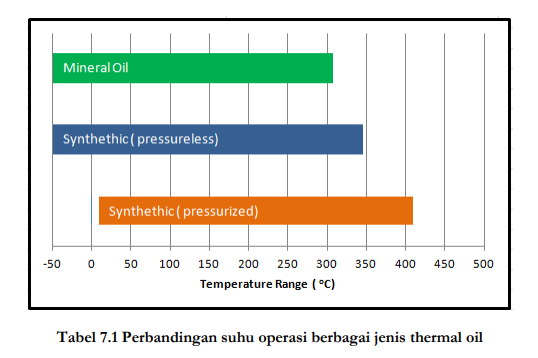

Table 7.1 Comparison of operating temperatures of various types of thermal oil

7.1.1 Hot Oil / Mineral à adjusted to the list above

Hot Oil / mineral is thermal oil extracted from petroleum. At the refinery, this crude oil is distilled with multilevel distillation into light fractions (gas and solvents), fuels (gasoline and diesel), lubricants, and also heavy traction (heavy fuel oil and asphalt). Hot oil / mineral originated from a piece of lubricant that is further processed and selected whose viscosity and stability are in accordance with its operating conditions and then marketed as thermal oil. In general, the operating temperature range of hot oil / mineral is 20ºC – 300ºC. Hot Oil has

several advantages compared to synthetic, namely at a cheaper price, no pungent odor, and ease of handling and ease of disposal because it does not form harmful byproducts of degradation Hot / mineral mineral deficiency is less stable at high temperatures because it has a limited degree of unsaturation (double bond) , more chemically reactive, and more susceptible to oxidation.

7.1.2 Synthetic

Synthetic oils, also called ‘aromatics’, are artificial liquids specifically produced for heat transfer applications. This synthesis oil consists of a benzene-based structure and contains diphenyl oxide / biphenyl, diphenyl ethane, diphenyl toluene, and diphenyl. This synthesis oil is formulated from organic and inorganic alkaline compounds and is used in aqueous form with concentrations ranging from 3% to 10%. The advantage of synthetic oil compared to thermal oil or non-synthetic oil lies in higher operating temperatures, which is up to 400 ºC. Whereas non-synthetic is usually only thermally stable to temperatures of 300ºC. Lack of synthetic oil is more expensive than mineral types. The higher the operating temperature, the higher the price.

7.1.3 Other

thermal fluids including Silicone Thermal fluid based on silicon and glycol hybrid fluid are only used in special applications that require process / product compatibility. This type of thermal fluid should not be used in general applications due to cost factors

7.2 Thermal oil selection

Themal fluid has many variations in terms of kinematic viscosity, operating temperature, pour point, boiling point and flash point. Therefore there are many factors to consider when selecting thermal oil for heat transfer systems. The main thing is as follows.

7.2.1 Safety and Fire Prevention

In addition to the design features of the system, fluid selection also greatly influences the likelihood of fire and safety. Because the thermal oil system always uses fuel, air and ignition sources, the risk of fire is always there. However, factories can reduce the risk of these fires by choosing the right thermal oil. When choosing thermal oil, there are three factors to consider: the flash point, the fire point and the auto ignition temperature.

• Flash Point – the temperature at which a fluid will produce steam and ignite when exposed to an ignition source.

• Fire Point – The temperature at which the fluid will produce steam and can support continuous combustion. Hotspots are usually 5ºC to 35ºC higher than the Flash Point.

• Auto-ignition Temperature (AIT) – The temperature at which the fluid will ignite on its own without a lighter.

In thermal oil systems, flash points, fire points and Auto ignition temperatures must be understood in the context of actual operating conditions. So that the fluid vapor can ignite, the fluid must be at conditions close to the flame temperature of the ignition source close enough to the surface to ensure minimum vapor concentration.

If there is a leak in the coil, the thermal fluid will immediately drop in temperature quickly falling below the flash point (flash point) due to exposure to air. Flash points and fire points describe the nature of fluid volatility or its ability to produce steam at a certain temperature. If a leak is severe enough, the liquid with a low flash point will tend to evaporate more, so the potential for fire will be greater. Thermal oil systems should not be run at temperatures higher than auto ignition temperature. Auto ignition temperature (AIT) and thermal stability of a thermal oil are the two main factors in fluid selection. System operating conditions must be far below Auto ignition temperature Some fires do occur due to fire in isolation, no flow, or cracks in the coil and leakage. However, fires caused by operating conditions above Auto ignition temperature rarely occur because the selection of fluids has been done properly.

7.2.2 Thermal stability

Thermal stability is the ability of a thermal fluid to withstand molecular damage caused by heat stress. The relative thermal stability test is carried out to determine the bond strength of a thermal fluid molecule at a certain temperature and then compared with other thermal fluids at the same temperature and the same test conditions. Thermal stability is a major factor in determining the maximum operating temperature of a liquid. This is the maximum temperature recommended by the manufacturer for thermal fluid to be used and in a stable condition. The use of thermal oil that exceeds the maximum operating temperature recommended by the manufacturer will increase the destruction / degradation exponentially. Excessive degradation will form byproducts such as coking, increased fouling (crust) and also a decrease in heat transfer efficiency. In operations above temperatures of 300ºC, synthetic types of thermal oil should always be used because they will be far more thermally stable than mineral / hot oil.

7.2.3 Heat transfer efficiency Heat

transfer efficiency is expressed by the heat transfer coefficient. The higher the coefficient of heat transfer, the greater the ability of thermal oil to conduct or transfer heat. Overall heat transfer coefficient (overall heat transfer coefficient) can be calculated using information about temperature, density (viscosity), viscosity, thermal conductivity and

specific heat capacity (specific heat capacity) on the flow velocity and diameter of the pipe determined. The heat transfer coefficient of each producer and each type of thermal oil can then be evaluated and compared.

At certain temperatures, the heat transfer coefficient of thermal oil can differ by up to 30%. This is influenced by the thermal resistance factor of other components in the system. The higher the heat transfer coefficient of a fluid, the smaller the size of the thermal oil system required. Therefore, the replacement of thermal oil with other types with higher heat transfer coefficients can increase production and / or

reduce energy costs. Most synthetic thermal oils will have a much higher efficiency than hot oil (minerals) at temperatures of 150ºC – 260ºC. Above the temperature is 260- 310ºC difference

the efficiency between hot oil (mineral) and synthetic aromatic type is not very significant. While the synthetic oil type paraffin white oil will have a higher efficiency than synthetic aromatic types.

7.2.4 Costs

As already mentioned, the higher the operating temperature of thermal fluid, the higher the price. Synthetic synthetic oil that can be used at temperatures above 340ºC can be 2-3 times more expensive than hot oil / minerals which on average operate below 300ºC . While aromatic thermal oil which operates at temperatures of 300ºC to 340ºC is 1.5 – 2 times more expensive than hot oil / minerals.

8. Application of Thermal Oil in Various Industries

8.1 Steam Generation for Industrial Processes

Looking at the recent development of Thermal Oil Heaters, it is predicted that in the next few years thermal oil will slowly replace the position of High Temperature Steam Boiler as a heating medium in industrial processes. Industries that use Thermal Oil Heaters for example:

• Inks and Dyes

• Laundry

• Vegetable Oil Deodorisers

• Paper and Conversion Machines

• Printing & Packaging Machines

• Adhesives

• Autoclaves

• Chemical Industry Processes

• High-temperature Distillation

• Asphalt

• Food processing for Grilling & Frying

• Shipping

• Rubber and Rubber

• Storage Tanks for Oil and Asphalt

At present most of the high pressure steam (above 30 bar) is always produced using fuel gas or oil. The main reason for using fuel gas or oil is the simplicity of the system and minimizing the costs of additional services. Actually high pressure steam can be produced using thermal oil as a heat source to boil water and convert it to steam. This tool is often called unfired / Indirect steam generator or Organic Steam generator (OSG)

8.2 Indirect / Organic Steam Generator (OSG)

Thermal oil has been used as a heating medium to produce saturated and superheated steam in several industries because it is the most cost effective way.

• In some countries, there are regulations that require continuous monitoring of stam boilers by certain qualified staff. Meanwhile, indirect steam generators are not needed.

• In a factory where two heat sources are needed, namely themal oil and steam simultaneously, the plant does not need to install a thermal oil heater and steam boiler simultaneously. The use of OSG combined with Thermal Oil Heater is an ideal and simple solution because with only one heat source, i.e.

thermal oil can simultaneously produce hot thermal oil and steam OSG’s operating principle is quite simple, namely Thermal Oil Heater will heat the circulating thermal oil in the OSG heating pipes. The heat will be transferred to water which will then change to a vapor phase at the desired pressure. The OSG system will be equipped with process controls to adjust steam pressure based on usage level and temperature and the flow rate of thermal oil is automatically adjusted to maintain steam requirements. Steam with a variety of pressures can be produced using these principles. Starting from low pressure 5 bar (g), medium 20 bar (g), even high pressure up to 70 bar (g).

The main advantage of a thermal oil heater is its ability to be utilized at several temperature levels, from high, medium to low temperatures in the same industrial process using various applications. The combination of OSG and Thermal Oil can be used

The main advantage of a thermal oil heater is its ability to be utilized at several temperature levels, from high, medium to low temperatures in the same industrial process using various applications. The combination of OSG and Thermal Oil can be used

in industries:

1. Food industry for use in frying and sterilization / evaporation processes. Thermal oil can be used as

a frying medium and OSG as a source of steam.

2. Cooking oil refineries that require low pressure steam (for heating), medium pressure steam (for vacuum) and high pressure steam (for final heater deodorizer). The combination of Thermal Oil as a heat source and OSG as a steam producer can produce steam with several different pressures.

3. The Laundry Industry can utilize Thermal Oil as a heat source for irons and also produce steam needed for washing machines. In general, the use of a combination of Thermal Oil and OSG in industries that require some type of heating level will have savings on capital investment of around

20-30% compared to a separate system Thermal Oil and Steam Boiler. While savings in operational costs will occur because there is no need for maintenance and also a decrease in operational costs when replacing fuel into coal / biomass.

8.3 Power Plants use Thermal Oil

Thermal power plants can be classified into closed thermal cycles and open thermal cycles. Open thermal cycle uses liquid or gas fuel and for diesel engines and gas turbines. This fuel is then burned either directly in the internal combustion engine / chamber and then goes to the open gas turbine for expansion. In a closed thermal cycle, combustion and power generation cycle occur in separate places. The separation occurs by the transfer of heat from the combustion gases to the media process in the secondary cycle. By separating fuel and engine, the engine will only come in contact with clean heating media. Therefore unwanted particles contained in the fuel and flue gas will be safe for the engine. Steam generators by using the thermal oil system to produce electricity are mostly done by small-scale electricity users in Europe, especially those who use biomass as a fuel source. The conventional way to produce electricity is to use Steam Rankine Cycle (SRC), which uses steam from the Steam Boiler to drive

Steam Turbine or Steam Engine.

But now more commonly used ORC (Organic Rankine Cycle) systems compared to SRC. ORC system is the use of thermal oil to heat vapor refrigerant / organic fluid with a large molecular weight to produce a certain pressure that can be used as a turbine drive.

The advantages of the ORC system compared to the SRC system are:

• No corrosive water is used

• No chemical treatment is needed expensive one.

• No demineralized water make up needed

• Does not require special operators

• Higher heat use efficiency especially for small capacities

• Can operate by utilizing waste heat

9. Thermal Oil Installation

9.1. Piping design

Piping design is very important in thermal oil systems. The choice of pipe size must be done properly, if the pipe used is too small it will inhibit the flow of thermal oil so that there will be a reduction in capacity. Continuous capacity reduction can result in overheating and coking formation which will reduce the life of thermal fluid. If proper pipe size has been chosen, to prevent the possibility of overheating a flow switch must be used which is useful as an interlock that will turn off the burner automatically when slowing down of thermal oil flow or no flow condition. Piping used should use schedule 40 pipe and should avoid the use of thread / thread fittings. The pipe must be cleaned from dirt before connection and welding joints must be tested using compressed dry air or nitrogen gas. And never use water to test piping. When designing pipes for thermal oil systems, designers must be sure that the material in the system matches the temperature and operational pressure. Carbon steel, Cast Steel, stainless steel and ductile iron are suitable materials for use in thermal oil systems. While brass, bronze, aluminum and cast iron cannot be used. The designer must be sure that the material in the system matches the temperature and operational pressure. Carbon steel, Cast Steel, stainless steel and ductile iron are suitable materials for use in thermal oil systems. While brass, bronze, aluminum and cast iron cannot be used. The designer must be sure that the material in the system matches the temperature and operational pressure. Carbon steel, Cast Steel, stainless steel and ductile iron are suitable materials for use in thermal oil systems. While brass, bronze, aluminum and cast iron cannot be used.

Leaks in thermal oil systems are usually caused by improper pipe design. Leaks, especially in large quantities, can be a direct cause of a fire, when hot thermal oil comes into contact with a fire / lighter. Most leaks are caused by damaged equipment, for example in the expansion joint, flexible hose, rotary union.

Some ways to prevent leakage:

Minimize the use of thread fittings that are unable to cope with thermal expansion and thermal contraction at high temperatures.

• Design a system that allows for sufficient expansion and contraction

• Expansion joints and flexible hoses must be able to move along their axes, avoiding sideways movement.

• Give sufficient lubrication to the rotary union and do it regularly. • Install isolation valves and bleed valves in pipes for each piece of equipment so that maintenance can be carried out without having to empty the entire system.

• For pump packing it is recommended to use a packing set consisting of end ring braided carbon / graphite fiber and middle ring made from preformed (pressed) graphite.

• Use spiral-wound carbon flanges or graphite gaskets.

• When installing the gasket, be sure to follow the order of tightening and torque according to the manufacturer’s recommendations. For mounting gaskets on valves, attach each packing ring completely then tighten the gland nuts slowly while moving the handle back and forth.

• If possible use bellows type valves and magnetic drive pumps without seals. Both of these equipment will provide excellent performance.

• Install the valve with the stem sideways so that if there is a leak it will fall under the steam and away from the pipe.

• All connections greater than 25 mm must be flange or welded.

As part of the thermal oil commissioning procedure, all pipes in the system must be tested with dry water or nitrogen in advance to find out if there is a leak in the welded joints and packing. All leaks must be repaired before thermal oil can be run.

9.2 Flow Control

The thermal oil piping system must be equipped with flow control so that fluid flow is guaranteed to flow smoothly and continuously in the heating pipes and coils. This flow control is connected directly to the burner and is equipped with an alarm. If there is damage to the pump, filter clogging or other problems that cause the condition there is no flow in the pipe, this problem will be immediately detected by the flow control and will instruct the burner to stop so that no more heat is given to the heating coil.

If the coking process continues over a long period of time, the charcoal layer will thicken and further disrupt heat transfer. Because of overheating, coking can cause cracks in the pipe and continue to leak thermal oil. This condition must be avoided and anticipated by installing flow control:

1. Mechanical flow switch on the main oil flow

2. Differential Pressure Flow Switch

3. High Pressure Regulating Valve between line suction and pump discharge

9.3 Temperature Control The

precision of temperature control determines the design of the Thermal oil system circuit. When a very precise temperature control is needed, a dual circuit can be used which consists of a primary circuit and a secondary circuit. At this dual circuit, the primary circuit temperature is higher around 10 – 30 oC above the secondary circuit, depending on the amount of heat load. This dual circuit can also be used on systems that require two different thermal oil temperatures. If three thermal oil circuits are needed with different temperatures, a triple circuit can also be made.

9.4 Isolation

Fire incidents in the thermal oil circuit are very rare. If there is a fire, sometimes the fire comes from leaky piping seepage, packing then seep into insulation made of rock wool. If the insulation protector is damaged, the hot thermal oil will come into contact with air, which can cause a fire. The insulation used should be from the insulation of non-porous material. Avoid the

use of insulation that can permeate fluids such as Calcium Silicate or fiberglass. However, if it is not possible, then connections that use packing and points of connection that are prone to leakage need not be isolated but are only given a kind of metal shield to prevent direct contact with humans.

10. Maintenance

Care System

design the right system, the right way of operation and accompanied by regular maintenance is the best way to prevent problems.

10.1 Periodic Fluid Analysis

Fires caused by cracking of the heating coil are relatively rare, but sometimes they can occur. Cracks on the heating coil are caused by excessive thermal cyclic, overheating or the position of the coil is too close to the burner flame. If there is a crack in the heating coil, the leaky liquid will immediately burn, and come out along with the flue gas and is marked by the appearance of black smoke in the chimney. Another indication is the operation of the temperature sensor placed on the flue gas that marks the thermal oil must be stopped for inspection.

Thermal oil in hot conditions is very easily oxidized by air, but it must be known that the Thermal oil heater system is a closed cycle where there is no chance to come into contact with air except through an expansion tank. Therefore the temperature of the thermal oil in the expansion tank must be maintained at a temperature close to the temperature of the surrounding air equipped with a deaerator and thermal buffer tank or by filling the top of the expansion tank with an inert gas, such as nitrogen. However, if a leak occurs when the system is not operating, thermal fluid will continue to leak into the combustion chamber due to pressure from expansion tanks and overhead pipes. In the most serious cases, liquid forms in large pools in the heater during a prolonged shutdown. When the heater is turned on again, the entire puddle is joined and damaged

heating.

To prevent thermal cyclic in the bundle tube heater, the oversized size of the heater must be lowered. Thermal cracking in fluids can be detected by routine fluid analysis. Fouling on the coil is often caused by deposition due to fluid oxidation. Oxidation can occur if the expansion tank opens into the air. The reaction of hot thermal oil and air will produce a kind of tars and sludge which encloses the surface and reduces the efficiency of heat transfer. These deposits make hot spots on the heater and then crack. Oxidation can be prevented by routine thermal fluid analysis according to manufacturer’s recommendations, usually once a year 10.2 System checks for leaks System checks should be carried out every week to find out if there is an initial leak in the valve, flange, welding joint, instrument port and thread fitting. If the thermal oil system emits smoke it has become an indication that there is a leak in the system.

10.3 Regular

checking Pump checks must be done periodically because besides the burner, the pump is a component that needs a lot of maintenance. Pump alignment must be checked periodically. If mechanical seal changes are often carried out ie more than once a year the alignment must be checked. If there is a leak or a strange sound comes from the pump, it must be checked immediately. The ventilation system must also be checked regularly. Fog or steam coming out of the vent can indicate the system has been contaminated with water or the thermal fluid decomposition occurs. The catch tank located at the end of the relief valve expansion tank or ventilation path must also be checked regularly. If the operation is correct, the catch tank must be empty. If

until there is liquid in the catch tank further investigation must be carried out. Fluid flow must be maintained according to design and checked periodically. Pressure gauge can also help give an indication if there is a disturbance in the system, for example moving up and down quickly, or a pressure drop that is higher than normal conditions. All above preventive maintenance must be done to reduce the risk of

fire.

I am Edward Spector

Lorem ipsum dolor sit amet adipiscing elit.

Duis hendrerit porttitor purus, quis pulvinar lacus mattis in. Donec eros lectus, luctus eu tempor vitae, efficitur ac magna. Phasellus non metus at purus elementum bibendum. Fusce suscipit nibh non tellus tincidunt, sed vulputate tellus eleifend. Etiam facilisis dapibus imperdiet. Aliquam justo purus, sollicitudin non lectus id, venenatis rhoncus lorem. Sed vel ornare ante.

Vestibulum vel nulla at nibh scelerisque fringilla. Aliquam id lectus in elit rutrum tristique. Fusce id urna id odio vulputate vehicula eu non ligula. Ut consectetur malesuada augue. Proin eget sem vitae est tincidunt varius eget sed ante. Praesent eget neque bibendum, volutpat lectus in, rhoncus velit. Etiam nibh tellus, sollicitudin eu aliquam eu, pretium id nunc.

Looking for an Expert Advisor?

Just send me a message!

Brands I worked with

25

PUBLICATIONS

117

SHOWS

76

COMPANIES

84

AWARDAS

Upcoming Events

Nibh non tellus tincidunt

26th December 2018

Brand Design Strategy

Consectetur adipiscing elit. Vestibulum at porttitor mi. Phasellus rhoncus ultricies est pharetra finibus.

31st January 2019

Cross BEP Within 6 Months

Consectetur adipiscing elit. Vestibulum at porttitor mi. Phasellus rhoncus ultricies est pharetra finibus.

24th February 2019

Acquiring Old Businesses

Consectetur adipiscing elit. Vestibulum at porttitor mi. Phasellus rhoncus ultricies est pharetra finibus.

Comments

No comment yet.