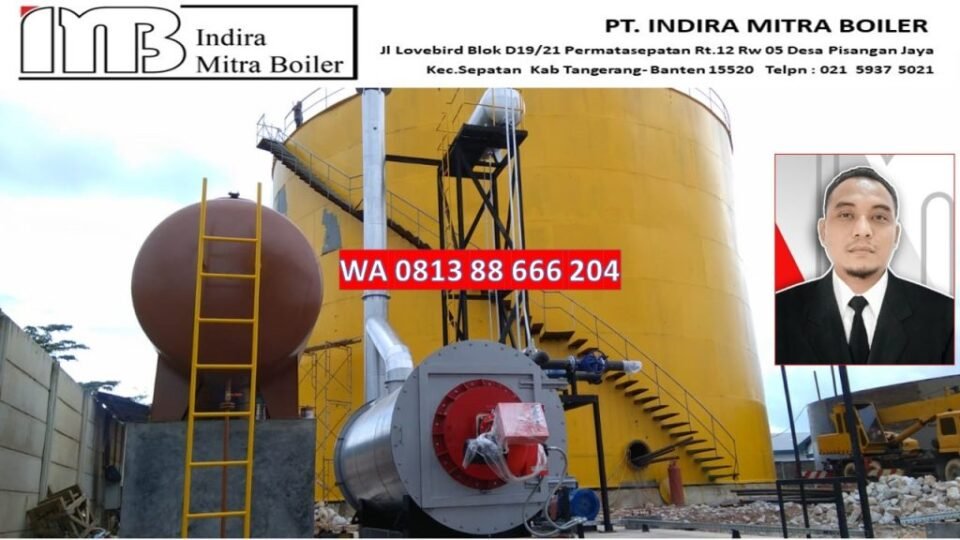

THERMAL OIL HEATER 100 MCAL- 600 MCAL Maker PT Indira Mitra Boiler

Manufactur Thermal oil heater IMB

Perushaan pembuat thermal oil hetaer (boiler oil) dengan kapasitas 100 Mcal hingga 600 Mcal . perushaan pt indira mitra boiler (PT IMB) yang berdiri sejak tahun 2015 di tangerang banten. thermal oil hetaer IMB terkenal ... Read More